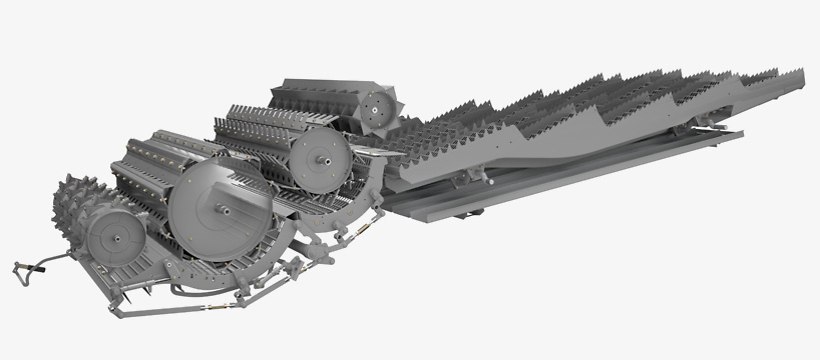

The new heart: APS SYNFLOW WALKER

With the APS SYNFLOW WALKER, the LEXION 6000 and 5000 set new standards for the threshing and separation performance of straw-walker combine harvesters. The all-new threshing unit features a 450 mm pre-accelerator drum, a 755 mm threshing drum with ten rasp bars and an additional separator drum with a diameter of 600 mm ahead of the impeller. The width of the unit is 1,700 mm in the 6000-series models and 1,420 mm in the 5000-series models. The large drum diameters create low contact angles of 132° (threshing drum) and 116° (separator drum). These characteristics, together with the synchronisation of the drum speeds, enable a straight, gentle and fuel-saving crop flow. The resulting active separation areas measure 3.18 m2 and 2.66 m2 respectively.

For fast adaptation to all crop types and operating conditions, all the threshing concave segments are adjusted hydraulically and in parallel in CEBIS. An overload protection system provides protection against blockages. A concave bar can be pivoted into the crop flow ahead of the threshing drum. This allows the aggressiveness of the unit to be controlled extremely precisely, for reliable deawning in barley, for example. As with all other threshing unit parameters, the control system for the bar is integrated in CEMOS AUTOMATIC. All the concave segments are accessible from the side and can be replaced easily. With drum speeds of between 160 and 920 rpm, APS SYNFLOW WALKER is suitable for all threshing crops.

Secondary separation is performed by six straw walkers in the LEXION 6000 and by five straw walkers in the LEXION 5000, all of which are 3,800 mm long. The respective straw walker areas are 6.46 m2 and 5.40 m2.

JET STREAM cleaning and new QUANTIMETER

The new straw-walker models are equipped with the JET STREAM cleaning system familiar from the existing LEXION hybrid combine harvesters. The system works with six or eight turbine fans, depending on the model. A dual ventilated step performs intensive pre-cleaning. The long flow compensation channel delivers a high-pressure airflow to the sieves. The sieves and fan can be adjusted electrically from the cab. With the 3D function, the cleaning system can actively compensate for side slopes of up to 20 %.

The new QUANTIMETER works with an impact plate at the grain elevator delivery point and measures the yield without requiring the thousand grain weight. Only one calibration process is required annually per crop type and this can be performed from the cab. As the various calibration factors for different crop types can be stored very easily, crop type changes can be performed quickly.